Our Wood: Pressure-Treated Scots Pine

The foundation of every KAMY playground is premium-quality, pressure-treated Scots pine (Pinus sylvestris). Sourced from Scandinavian and Eastern European forests, where slow growth produces dense grain and excellent mechanical properties, this species is the ideal choice for outdoor playgrounds: easy to machine, holds screws securely, and withstands decades of weathering when pressure-treated.

15+

year lifespan

Tanalith E Autoclave Treatment

Tanalith E treatment is an industrial pressure-based autoclave impregnation process. The timber is placed in a sealed autoclave chamber, a vacuum is created, then the Tanalith E preservative solution is forced deep into the wood cells under high pressure (8–14 bar). The active ingredient (copper-based, chromium- and arsenic-free formula) chemically bonds to the wood fibres and will not leach out from rain or ground moisture. The process provides comprehensive protection against fungi, mould, insects, and decay. It is approved under the EU Biocidal Products Regulation (BPR, 528/2012/EU) and is fully child-safe.

Manufacturing Process

Sourcing

First-grade Scots pine from FSC-certified forestry operations. The timber is kiln-dried (moisture content below 18%), graded, and only A/B quality class is used in production.

Autoclave Treatment

Tanalith E pressure treatment in industrial autoclave: vacuum → pressure impregnation (8–14 bar) → post-drying. The process ensures deep penetration of the preservative throughout the full cross-section of the timber.

Quality Control

Rigorous multi-stage inspection: moisture content measurement, strength testing, surface quality checks, dimensional accuracy, and sample testing of preservative penetration depth.

Durability

Pressure-treated Scots pine is rated Use Class UC3–UC4, meaning it is suitable for ground-contact and permanent outdoor applications. The lifespan exceeds 15 years with no maintenance — with regular oiling or staining, 20–25 years is achievable. After treatment, the wood will not rot, resists fungal infection, and is protected against wood-boring insects (woodworm, carpenter ants). Structural strength does not diminish significantly over the years.

Sustainability

Scots pine is one of Europe's fastest-renewing timber resources: in Scandinavian and Baltic forests, more trees are planted each year than harvested. Our suppliers source exclusively from FSC (Forest Stewardship Council) certified forestry operations, guaranteeing responsible forest management. Pressure treatment extends service life, reducing the need for replacement and waste. At end of life, treated timber can be professionally disposed of.

Why Scots Pine Over Tropical Hardwood?

Tropical hardwoods (teak, bangkirai, cumaru) are naturally durable but significantly more expensive (3–5×), harder to machine, and often of questionable origin. Pressure-treated Scots pine delivers comparable longevity at a more accessible price point, from verifiably sustainable sources. It is also lighter, making assembly easier and shipping costs lower. The natural resin content of Scots pine provides an additional mild insect-repellent effect.

Natural Wood Characteristics

Wood is a natural, living material — every plank and beam is unique. Below we describe phenomena that may occur during processing and outdoor use. These are not manufacturing defects but inherent properties of natural timber. They do not affect durability, structural integrity, or safety, and do not constitute grounds for warranty claims.

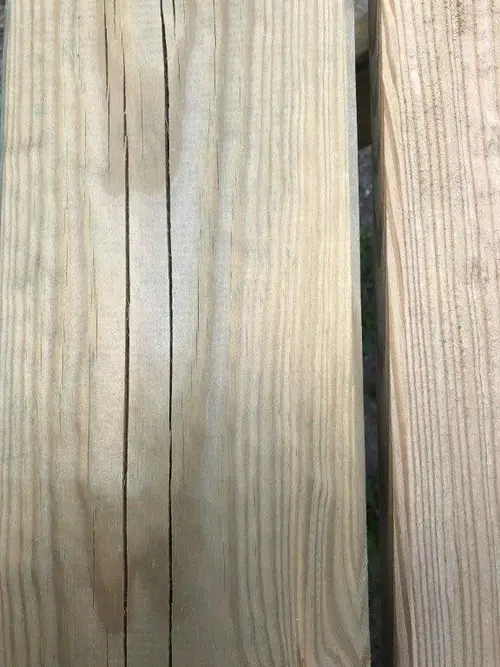

Cracks, Warping & Twisting

As wood dries, it continually loses moisture, creating internal stresses. This results in hairline cracks, surface checks, or deeper drying splits — particularly near the ends (end grain). Wider, thinner cross-sections (e.g. cladding boards, railings) are more prone to twisting and warping. These movements are most intense during the first 6–12 months after installation, until the wood reaches equilibrium moisture content. Cracks do not weaken the wood structurally, and the preservative continues to protect the wood along crack surfaces.

Knots & Resin Pockets

Knots mark the growth points of branches and are inherent to Scots pine. Their size, shape, and density vary from piece to piece. Around knots, the grain direction changes, creating different surface patterns. Resin pockets (closed cavities filled with resin) also occur, especially in younger timber. In warm weather (above 30°C), resin may liquify and seep to the surface — appearing as sticky, amber-coloured droplets. Leaked resin can be removed with turpentine or a specialist wood cleaner, but may reappear. This phenomenon diminishes over time.

Rough Surfaces & Splintering

While every KAMY product is machined with industrial planers, the natural grain structure of wood means a perfectly smooth finish cannot be guaranteed at every point. Around knots, the grain twists; heartwood and sapwood areas have different hardness — all of which can create surface irregularities. During outdoor use, repeated wetting and drying cycles may cause surface splintering. We recommend lightly sanding the most-used surfaces once a year with fine sandpaper (P120–P180), especially where children grip the wood.

Green Tint

After pressure treatment, the wood takes on a characteristic greenish tint — this is the natural colour of the copper-based preservative. Intensity depends on the wood's moisture content and sun exposure: freshly treated timber appears strongly green, then gradually fades to honey-brown and eventually grey-brown over several weeks. Sapwood (outer layer) and heartwood (inner core) absorb the preservative at different rates, so colour variations within the same board are normal. This evens out naturally over time.

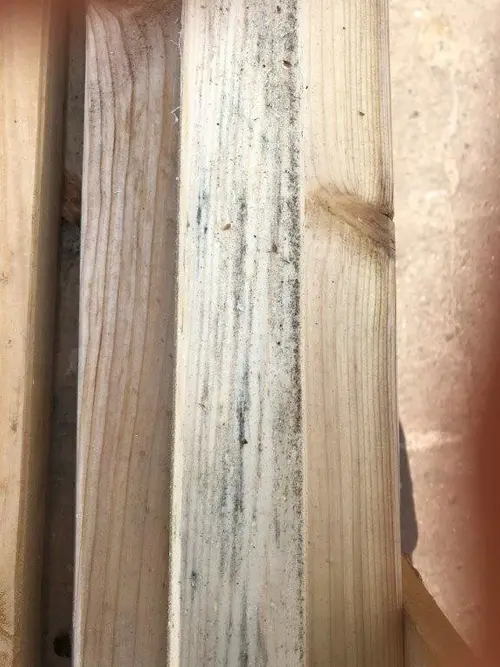

Mould & Surface Fungal Growth

If the wood's moisture content remains above 20% for extended periods (e.g. stored in packaging, without ventilation, in shaded or humid conditions), mould or algae spots may develop on the surface. These appear as black, grey, or greenish patches. Tanalith E treatment protects the wood's interior from decay but cannot entirely prevent surface mould growth. Prevention: store timber before installation in a well-ventilated, covered location, not stacked directly on top of each other. If mould does appear, it can be removed with a chlorine-free wood surface cleaner.

Colour Change & Browning

UV radiation from sunlight causes the wood's appearance to change continuously. In the first weeks, the greenish treatment colour transitions to honey-brown, golden-brown, then light brown. Sun-exposed and shaded sides change at different rates, which may cause temporary patchiness. The heartwood (darker core) and sapwood (lighter outer section) of softwoods colour at different intensities, sometimes creating a striped effect. After 1–2 seasons, the colour evens out. A uniform, warm tone can be achieved with stain or oil.

UV Greying (Patina)

UV radiation breaks down the top lignin layer of the wood, causing the surface to gradually turn silver-grey — regardless of treatment. This natural ageing process (patina) does not reduce the wood's durability or load-bearing capacity. Greying is most intense in the first 1–2 years, then slows. If you wish to preserve the original wood colour, applying UV-filtering stain or exterior wood oil 1–2 times per year is recommended. Important: greying does not indicate decay — the preservative inside the wood continues to provide full protection.